Company History

The InCom Group, set up in 1997, starts its activity as an exclusive subcontractor manufacturing fiberglass components for a multinational manufacturer of wind turbine blades. So that, over the past 20 years, InCom has acquired an extensive knowledge of engineering, processes and materials focusing on optimized Core Kits for wind blades.

Timeline

A BRIEF WALK THROUGH OUR HISTORY

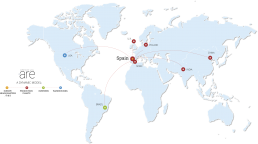

Global Support

Spain: Headquarters and R&D

The centre of our knowledge base and the place where we are constantly developing new concepts, products and processes. In fact, we are increasing the number of engineering hours to achieve the goal of creating value to the entire Supply Chain as the industry evolves and challenges arise.

Key Figures

11

countries

904

employees

36,314

kits in 2017

A Global &

Partnership Model

R&D / C.I.S.

Because we invest in Research and Development (R&D) and Continuous Improvement Services (CIS), kits supply is just the beginning. As a part of our full service supply, we send engineering teams to our customer’s production plants to make on-site improvements, resulting in a greater optimization of the customers' production processes, in terms of cycle-time and cost, etc.

WAREHOUSING

At InCom, we are designing and operating tailor-made supply chain solutions to meet our customers' needs. We are in the position to provide global JIT delivery to wherever our customers require.

DESIGN ENGINEERING

InCom’s goal is to create value for our customers, not only through manufacturing but also through sharing knowledge. That is why, thanks to our highly qualified engineering team, we constantly strive to give tailor-made engineering solutions, resulting in a positive impact on our services portfolio and thus, in our customers’ satisfaction.

PRODUCTION/ INNOVATION

As a global kit manufacturer, we pride ourselves on offering excellence in producing kits, through advanced manufacturing techniques in compliance with safety standards, cost reduction and time optimization, resulting in an unmatched quality per kit.

Global Industrial Consultancy Services

InCom’s kits are a vehicle for conveying industrial know-how, skills and productive capabilities, that in combination with the Industrial Consultancy Services on our portfolio, makes it a highly evolved manufacturing element suitable of being distributed to anywhere in the world.

Focused on Kit Solutions

As a GLOBAL KIT MANUFACTURER, we pride ourselves on offering excellence in each of our kits, through advanced manufacturing techniques in compliance with safety standards, cost reduction and time optimization, resulting in an unmatched quality per kit.

InCom’s kits are a vehicle for conveying industrial know-how, skills and productive capabilities, that in combination with the Industrial Consultancy Services on our portfolio, makes it a highly evolved manufacturing element suitable of being distributed to anywhere in the world.

INDUSTRIAL

In-house Client Product Optimization

Integration with Client Workflow

In-house Raw Material Testing

On-site Layup Assistance

Process Engineering

Tooling Design

QUALITY

Process Failure Mode And Effects Analysis (PFMA)

Advanced Product Quality Planning (APQP)

Lean Manufacutring Tools Implementation

Production Plan Approval Process (PPAP)

Scrap Reduction Program Execution

Technical Audit

KIT DESIGN

Optimized for reducing cost

Product certification

Testing & validation

Preliminary design

Detailed design

SUPPLY CHAIN

Customised Kit configuration to facilitate customers workflow

Local warehousing of inventories close to your plant

Continuous improvement to drive out waste

JIT Global Logistic Support

Supply Chain Management